One of the concerns of a quilter using fusible web is the problem with scrim on batting. (I know this because I learned the hard way and am still in recovery.)

Scrim is a thin, non-woven plastic-like fiber placed on the back of some batts. When making batting, manufacturers needle or force cotton/poly fibers into the scrim to hold those tiny fibers in place.

Scrim is a thin, non-woven plastic-like fiber placed on the back of some batts. When making batting, manufacturers needle or force cotton/poly fibers into the scrim to hold those tiny fibers in place.

Scrim is not used on all batting types. (Wool is generally scrim free.) But if it is used on a cotton, poly, or combination batting, it can mess up your fused quilt.

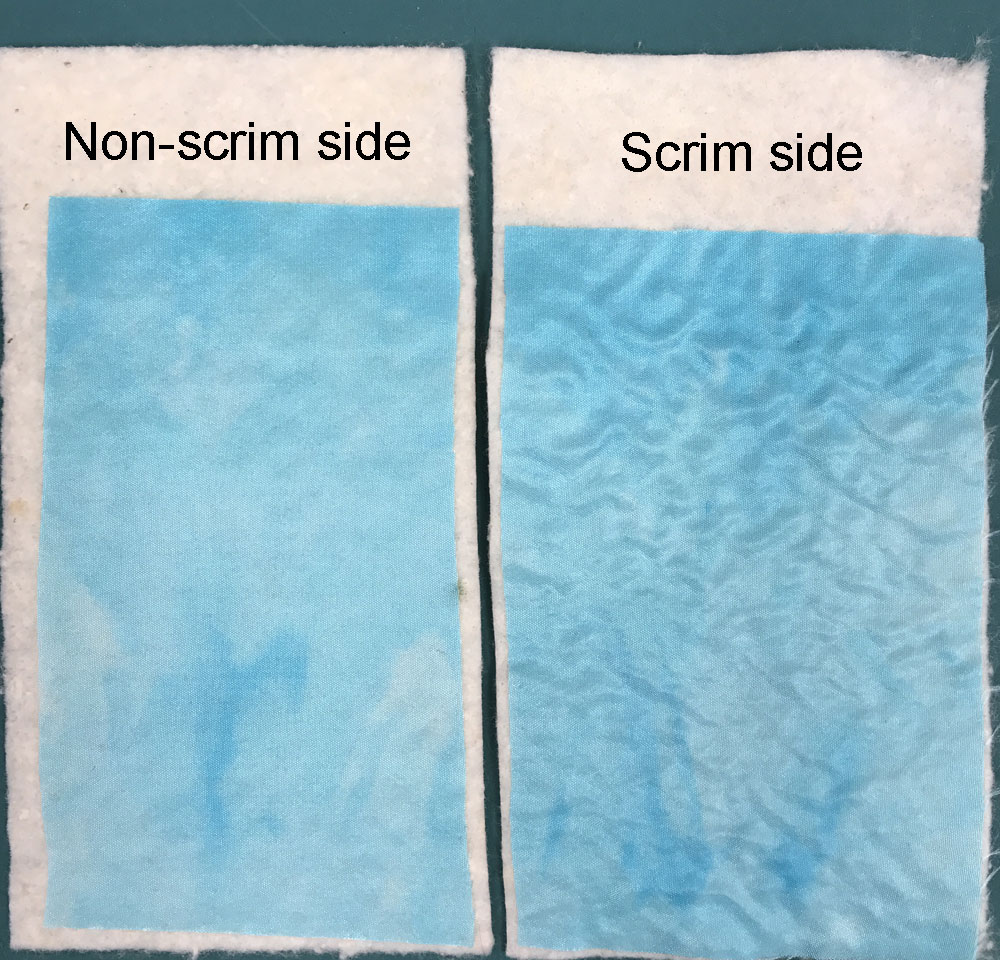

When fabric backed with fusible web is ironed to the scrim side of the batting, the fabric will ripple. When fabric backed with fusible web is ironed to the NON-scrim side of batting, the fabric appears flat.

When fabric backed with fusible web is ironed to the scrim side of the batting, the fabric will ripple. When fabric backed with fusible web is ironed to the NON-scrim side of batting, the fabric appears flat.

How to Detect the Scrim Side of Batting

- Feel the batting. When you run your hand across the scrim side of batting, it feels rough and coarse compared to the other side of the batting.

- The scrim side may appear pilled or pimply.

- Scrim may have a slight sheen from the plastic coating rather than a matte finish like the non-scrim side.

- You may be able to lift or separate the scrim at a corner of the batting. But don’t take it off.

How to Detect the Non-scrim side of the Batting

- The non-scrim side of the batting feels soft.

- It appears fluffy and fuzzier than the flat side of the batting.

- It has “dimples” or pock marks from the needling.

- Some batts have a “seedier” side or have more cotton hulls and seeds. This is the non-scrim side of that batting.

Test your Batting

If you are fusing fabric directly to the batt, test the batting first. Iron just a corner of the quilt to the batting. If it ripples or waves, pull the quilt off the batting and apply the quilt top to the other side of the batt.